Difference between revisions of "Category:Satoru KUKINO"

Jump to navigation

Jump to search

Wikipatents (talk | contribs) (Updating Category:Satoru_KUKINO) |

Wikipatents (talk | contribs) (Updating Category:Satoru_KUKINO) |

||

| Line 2: | Line 2: | ||

=== Executive Summary === | === Executive Summary === | ||

| − | Satoru KUKINO is an inventor who has filed | + | Satoru KUKINO is an inventor who has filed 8 patents. Their primary areas of innovation include TURNING; BORING (arrangements for copying or controlling (5 patents), Diamond (2 patents), TURNING; BORING (arrangements for copying or controlling (2 patents), and they have worked with companies such as SUMITOMO ELECTRIC HARDMETAL CORP. (7 patents), Sumitomo Electric Hardmetal Corp. (1 patents). Their most frequent collaborators include [[Category:Akihiko UEDA|Akihiko UEDA]] (4 collaborations), [[Category:Michiko MATSUKAWA|Michiko MATSUKAWA]] (4 collaborations), [[Category:Yuh ISHIDA|Yuh ISHIDA]] (3 collaborations). |

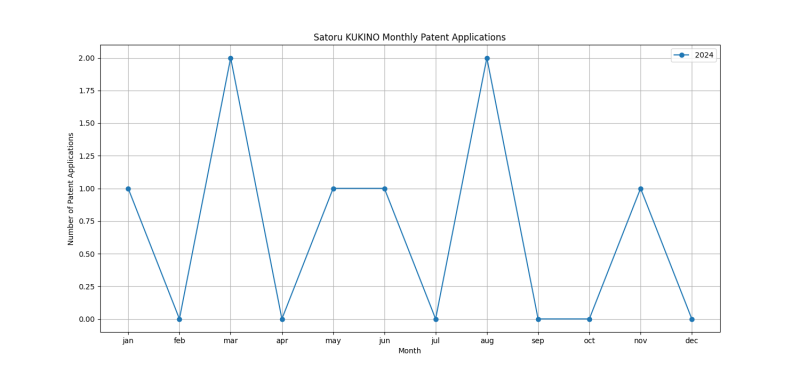

=== Patent Filing Activity === | === Patent Filing Activity === | ||

| Line 11: | Line 11: | ||

==== List of Technology Areas ==== | ==== List of Technology Areas ==== | ||

| − | * [[:Category:CPC_B23B27/148|B23B27/148]] (TURNING; BORING (arrangements for copying or controlling): | + | * [[:Category:CPC_B23B27/148|B23B27/148]] (TURNING; BORING (arrangements for copying or controlling): 5 patents |

| + | * [[:Category:CPC_C01B32/25|C01B32/25]] (Diamond): 2 patents | ||

| + | * [[:Category:CPC_B23B2226/315|B23B2226/315]] (TURNING; BORING (arrangements for copying or controlling): 2 patents | ||

* [[:Category:CPC_B23B2226/31|B23B2226/31]] (TURNING; BORING (arrangements for copying or controlling): 2 patents | * [[:Category:CPC_B23B2226/31|B23B2226/31]] (TURNING; BORING (arrangements for copying or controlling): 2 patents | ||

| − | * [[:Category: | + | * [[:Category:CPC_C23C14/0635|C23C14/0635]] (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents |

| − | * [[:Category: | + | * [[:Category:CPC_C23C14/0641|C23C14/0641]] (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents |

| + | * [[:Category:CPC_C23C14/0647|C23C14/0647]] (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents | ||

| + | * [[:Category:CPC_C23C14/0652|C23C14/0652]] (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents | ||

| + | * [[:Category:CPC_C23C14/30|C23C14/30]] (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents | ||

| + | * [[:Category:CPC_C23C14/32|C23C14/32]] (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents | ||

| + | * [[:Category:CPC_B23B2228/105|B23B2228/105]] (TURNING; BORING (arrangements for copying or controlling): 1 patents | ||

| + | * [[:Category:CPC_B23C2226/315|B23C2226/315]] (MILLING (broaching): 1 patents | ||

* [[:Category:CPC_C01P2004/62|C01P2004/62]] (INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS): 1 patents | * [[:Category:CPC_C01P2004/62|C01P2004/62]] (INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS): 1 patents | ||

* [[:Category:CPC_C01P2004/64|C01P2004/64]] (Nanometer sized, i.e. from 1-100 nanometer): 1 patents | * [[:Category:CPC_C01P2004/64|C01P2004/64]] (Nanometer sized, i.e. from 1-100 nanometer): 1 patents | ||

| Line 20: | Line 28: | ||

* [[:Category:CPC_C01P2006/80|C01P2006/80]] (Compositional purity): 1 patents | * [[:Category:CPC_C01P2006/80|C01P2006/80]] (Compositional purity): 1 patents | ||

* [[:Category:CPC_C01P2006/90|C01P2006/90]] (INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS): 1 patents | * [[:Category:CPC_C01P2006/90|C01P2006/90]] (INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS): 1 patents | ||

| + | * [[:Category:CPC_C04B35/528|C04B35/528]] (obtained from carbonaceous particles with or without other non-organic components): 1 patents | ||

| + | * [[:Category:CPC_B24D5/02|B24D5/02]] (TOOLS FOR GRINDING, BUFFING OR SHARPENING (abrading-bodies specially designed for tumbling apparatus, e.g. abrading-balls): 1 patents | ||

| + | * [[:Category:CPC_C04B35/522|C04B35/522]] ({Graphite (): 1 patents | ||

| + | * [[:Category:CPC_C04B2235/425|C04B2235/425]] (Graphite): 1 patents | ||

| + | * [[:Category:CPC_C04B2235/427|C04B2235/427]] (Diamond): 1 patents | ||

| + | * [[:Category:CPC_C04B2235/725|C04B2235/725]] (Metal content): 1 patents | ||

* [[:Category:CPC_C04B35/5831|C04B35/5831]] (based on cubic boron nitrides {or Wurtzitic boron nitrides, including crystal structure transformation of powder}): 1 patents | * [[:Category:CPC_C04B35/5831|C04B35/5831]] (based on cubic boron nitrides {or Wurtzitic boron nitrides, including crystal structure transformation of powder}): 1 patents | ||

* [[:Category:CPC_C04B38/0054|C04B38/0054]] (Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof (treating slag with gases or gas generating material): 1 patents | * [[:Category:CPC_C04B38/0054|C04B38/0054]] (Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof (treating slag with gases or gas generating material): 1 patents | ||

| Line 47: | Line 61: | ||

==== List of Companies ==== | ==== List of Companies ==== | ||

| − | * SUMITOMO ELECTRIC HARDMETAL CORP.: | + | * SUMITOMO ELECTRIC HARDMETAL CORP.: 7 patents |

| + | * Sumitomo Electric Hardmetal Corp.: 1 patents | ||

=== Collaborators === | === Collaborators === | ||

| − | * [[:Category:Akihiko UEDA|Akihiko UEDA]][[Category:Akihiko UEDA]] (3 collaborations) | + | * [[:Category:Akihiko UEDA|Akihiko UEDA]][[Category:Akihiko UEDA]] (4 collaborations) |

| + | * [[:Category:Michiko MATSUKAWA|Michiko MATSUKAWA]][[Category:Michiko MATSUKAWA]] (4 collaborations) | ||

| + | * [[:Category:Yuh ISHIDA|Yuh ISHIDA]][[Category:Yuh ISHIDA]] (3 collaborations) | ||

| + | * [[:Category:Hironari MOROGUCHI|Hironari MOROGUCHI]][[Category:Hironari MOROGUCHI]] (2 collaborations) | ||

| + | * [[:Category:Yuki TSUTSUMIUCHI|Yuki TSUTSUMIUCHI]][[Category:Yuki TSUTSUMIUCHI]] (2 collaborations) | ||

* [[:Category:Hirotsugu IWASAKI|Hirotsugu IWASAKI]][[Category:Hirotsugu IWASAKI]] (2 collaborations) | * [[:Category:Hirotsugu IWASAKI|Hirotsugu IWASAKI]][[Category:Hirotsugu IWASAKI]] (2 collaborations) | ||

* [[:Category:Takashi HARADA|Takashi HARADA]][[Category:Takashi HARADA]] (2 collaborations) | * [[:Category:Takashi HARADA|Takashi HARADA]][[Category:Takashi HARADA]] (2 collaborations) | ||

| − | * [[:Category: | + | * [[:Category:Nozomi TSUKIHARA|Nozomi TSUKIHARA]][[Category:Nozomi TSUKIHARA]] (1 collaborations) |

* [[:Category:Naoki WATANOBE|Naoki WATANOBE]][[Category:Naoki WATANOBE]] (1 collaborations) | * [[:Category:Naoki WATANOBE|Naoki WATANOBE]][[Category:Naoki WATANOBE]] (1 collaborations) | ||

| − | |||

| − | |||

| − | |||

* [[:Category:Rintaro SUGIMOTO|Rintaro SUGIMOTO]][[Category:Rintaro SUGIMOTO]] (1 collaborations) | * [[:Category:Rintaro SUGIMOTO|Rintaro SUGIMOTO]][[Category:Rintaro SUGIMOTO]] (1 collaborations) | ||

[[Category:Satoru KUKINO]] | [[Category:Satoru KUKINO]] | ||

[[Category:Inventors]] | [[Category:Inventors]] | ||

| + | [[Category:Inventors filing patents with Sumitomo Electric Hardmetal Corp.]] | ||

[[Category:Inventors filing patents with SUMITOMO ELECTRIC HARDMETAL CORP.]] | [[Category:Inventors filing patents with SUMITOMO ELECTRIC HARDMETAL CORP.]] | ||

Latest revision as of 17:13, 15 December 2024

Contents

Satoru KUKINO

Executive Summary

Satoru KUKINO is an inventor who has filed 8 patents. Their primary areas of innovation include TURNING; BORING (arrangements for copying or controlling (5 patents), Diamond (2 patents), TURNING; BORING (arrangements for copying or controlling (2 patents), and they have worked with companies such as SUMITOMO ELECTRIC HARDMETAL CORP. (7 patents), Sumitomo Electric Hardmetal Corp. (1 patents). Their most frequent collaborators include (4 collaborations), (4 collaborations), (3 collaborations).

Patent Filing Activity

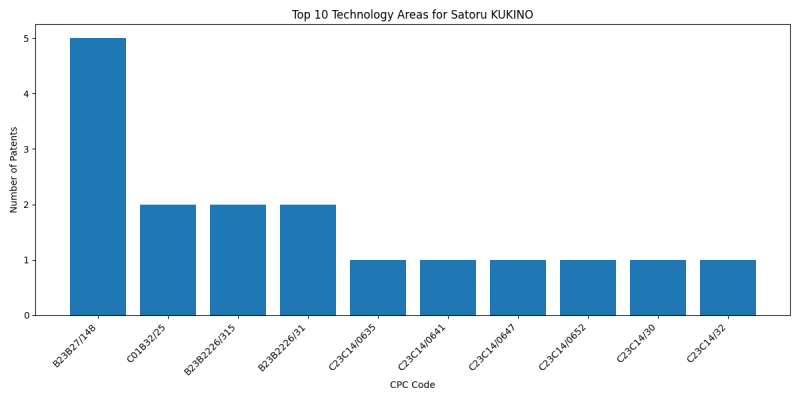

Technology Areas

List of Technology Areas

- B23B27/148 (TURNING; BORING (arrangements for copying or controlling): 5 patents

- C01B32/25 (Diamond): 2 patents

- B23B2226/315 (TURNING; BORING (arrangements for copying or controlling): 2 patents

- B23B2226/31 (TURNING; BORING (arrangements for copying or controlling): 2 patents

- C23C14/0635 (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents

- C23C14/0641 (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents

- C23C14/0647 (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents

- C23C14/0652 (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents

- C23C14/30 (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents

- C23C14/32 (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents

- B23B2228/105 (TURNING; BORING (arrangements for copying or controlling): 1 patents

- B23C2226/315 (MILLING (broaching): 1 patents

- C01P2004/62 (INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS): 1 patents

- C01P2004/64 (Nanometer sized, i.e. from 1-100 nanometer): 1 patents

- C01P2006/10 (Solid density): 1 patents

- C01P2006/80 (Compositional purity): 1 patents

- C01P2006/90 (INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS): 1 patents

- C04B35/528 (obtained from carbonaceous particles with or without other non-organic components): 1 patents

- B24D5/02 (TOOLS FOR GRINDING, BUFFING OR SHARPENING (abrading-bodies specially designed for tumbling apparatus, e.g. abrading-balls): 1 patents

- C04B35/522 ({Graphite (): 1 patents

- C04B2235/425 (Graphite): 1 patents

- C04B2235/427 (Diamond): 1 patents

- C04B2235/725 (Metal content): 1 patents

- C04B35/5831 (based on cubic boron nitrides {or Wurtzitic boron nitrides, including crystal structure transformation of powder}): 1 patents

- C04B38/0054 (Porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof (treating slag with gases or gas generating material): 1 patents

- C04B2235/3217 (Aluminum oxide or oxide forming salts thereof, e.g. bauxite, alpha-alumina): 1 patents

- C04B2235/3813 (Refractory metal borides): 1 patents

- C04B2235/3856 (Carbonitrides, e.g. titanium carbonitride, zirconium carbonitride): 1 patents

- C04B2235/386 (Boron nitrides): 1 patents

- C04B2235/3865 (Aluminium nitrides): 1 patents

- C04B2235/3873 (Silicon nitrides, e.g. silicon carbonitride, silicon oxynitride): 1 patents

- C04B2235/3886 (Refractory metal nitrides, e.g. vanadium nitride, tungsten nitride): 1 patents

- C04B2235/405 (Iron group metals): 1 patents

- C04B2235/762 (Cubic symmetry, e.g. beta-SiC): 1 patents

- B22F3/14 (WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER (making alloys by powder metallurgy): 1 patents

- B22F5/00 (Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product): 1 patents

- B22F9/04 (WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER (making alloys by powder metallurgy): 1 patents

- C22C1/05 (Mixtures of metal powder with non-metallic powder (): 1 patents

- C22C26/00 (Alloys containing diamond {or cubic or wurtzitic boron nitride, fullerenes or carbon nanotubes}): 1 patents

- B22F2005/001 (WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER (making alloys by powder metallurgy): 1 patents

- B22F2302/406 (WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER (making alloys by powder metallurgy): 1 patents

- B22F2998/10 (Processes characterised by the sequence of their steps): 1 patents

- B22F2999/00 (Aspects linked to processes or compositions used in powder metallurgy): 1 patents

- B23B27/20 (TURNING; BORING (arrangements for copying or controlling): 1 patents

- C23C16/27 (COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL (making metal-coated products by extrusion): 1 patents

Companies

List of Companies

- SUMITOMO ELECTRIC HARDMETAL CORP.: 7 patents

- Sumitomo Electric Hardmetal Corp.: 1 patents

Collaborators

- Akihiko UEDA (4 collaborations)

- Michiko MATSUKAWA (4 collaborations)

- Yuh ISHIDA (3 collaborations)

- Hironari MOROGUCHI (2 collaborations)

- Yuki TSUTSUMIUCHI (2 collaborations)

- Hirotsugu IWASAKI (2 collaborations)

- Takashi HARADA (2 collaborations)

- Nozomi TSUKIHARA (1 collaborations)

- Naoki WATANOBE (1 collaborations)

- Rintaro SUGIMOTO (1 collaborations)

Subcategories

This category has the following 9 subcategories, out of 9 total.